Fourways Civils

Beyond Concrete: Your Strategic Partner in National Development

At Fourways Concrete, we do more than just supply materials; we engineer solutions. Our Projects Division is the cornerstone of our commitment to building a stronger, more prosperous Zimbabwe. We are not merely a contractor but a dedicated partner, bringing strategic thinking, innovative design, and unparalleled expertise to every high-stakes civil and concrete engineering challenge. Our work is a testament to our mission: to be the leading, dynamic infrastructure development partner, contributing to the nation’s progress.

Get a Quote For Your Project

Our Core Competencies: The Fourways Advantage

- Engineering Innovation & Custom Solutions: Our team of experienced engineers thrives on complexity. We design and implement bespoke concrete solutions tailored to the unique demands of each project, ensuring optimal performance and cost-effectiveness.

- Proven Logistical Mastery: We have a demonstrated ability to manage and execute large-scale concrete placements, even in the most challenging environments. Our meticulous planning and execution guarantee timely delivery and seamless project flow.

- Specialized Mining & Industrial Expertise: We possess deep knowledge of the mining and industrial sectors, allowing us to provide specialized solutions that enhance safety, efficiency, and structural integrity.

- Unwavering Commitment to Quality & Sustainability: We utilize high-grade materials and rigorous quality control measures to deliver durable, long-lasting results. Our commitment to sustainable practices, including the use of recycled aggregate and a stringent waste management program, underscores our dedication to environmental stewardship.

Projects as Proof:

Our Portfolio of Excellence

Our projects are more than just a list of accomplishments; they are tangible proof of our values in action. Each case study demonstrates our ability to overcome challenges, innovate, and deliver exceptional results.

Then we show our projects here and we put pictures of our projects. When you open the pictures of there should be a short summary relating to what we were doing:

Project Showcase 1:

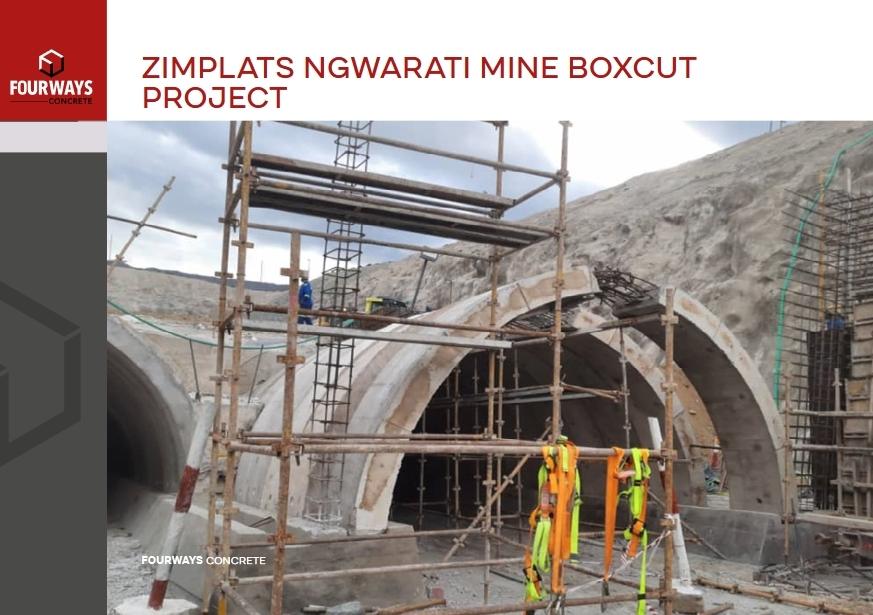

Ngwarati Mine Box Cut

The Challenge: Monumental Scale and Logistical Complexity

The development of the Ngwarati Mine Box Cut was an undertaking of immense proportions. The primary challenge lay in the sheer volume of materials required and the precision needed to execute the project on a tight schedule. This required not only the placement of 14,000m³ of high-strength concrete for the primary structures but also the management of 20,000m³ of gravel for the critical backfill and compaction phase needed to secure the tunnels.

The Fourways Solution: Integrated Execution and Resource Mastery

We deployed a comprehensive project management strategy to tackle this challenge head-on. Our solution was built on two pillars: logistical mastery and integrated execution. We established a seamless supply chain to manage the continuous delivery of concrete and gravel, ensuring no delays. Our on-site teams worked in a coordinated manner, sequencing the concrete pours with the extensive earthworks, ensuring that the backfill and compaction were completed to exacting engineering standards, guaranteeing the long-term stability of the tunnel structures.

The Impact

The successful completion of the Ngwarati Box Cut stands as a powerful demonstration of our capacity to manage and execute large-scale civil engineering projects. It proves our reliability in handling massive material volumes and our expertise in critical ground engineering and compaction.

Project Showcase 2:

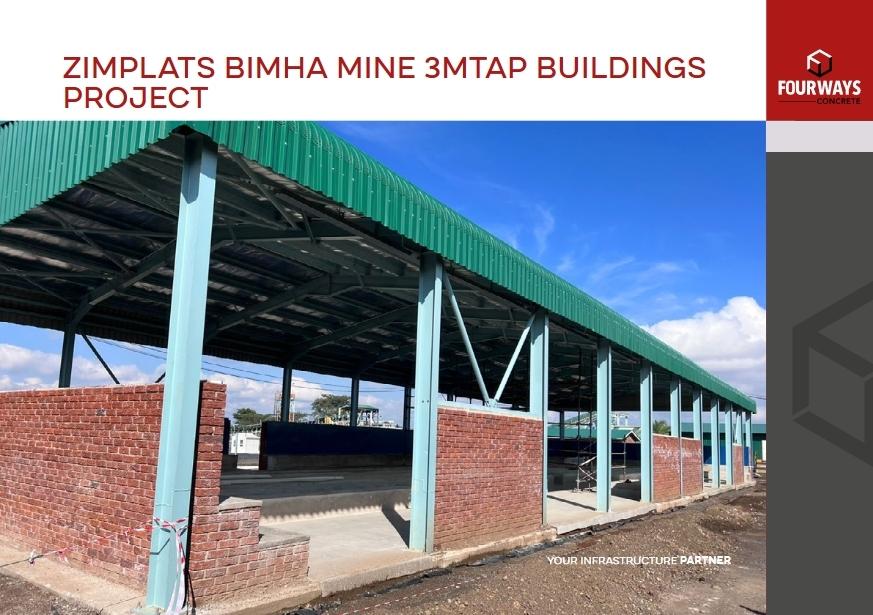

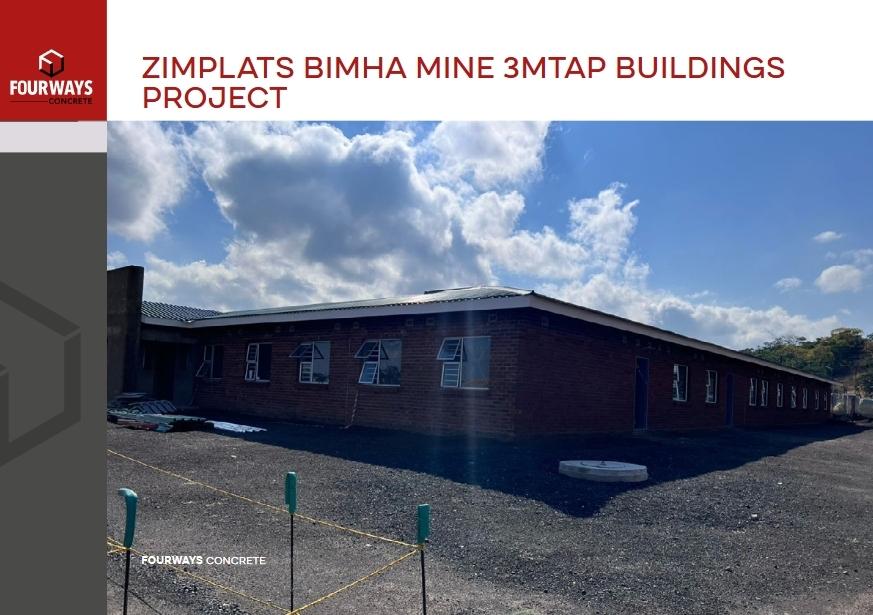

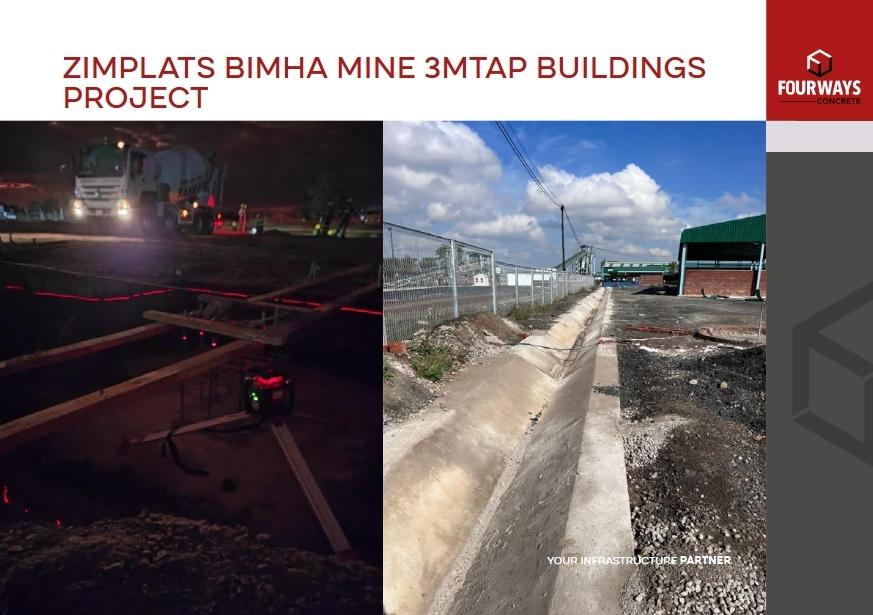

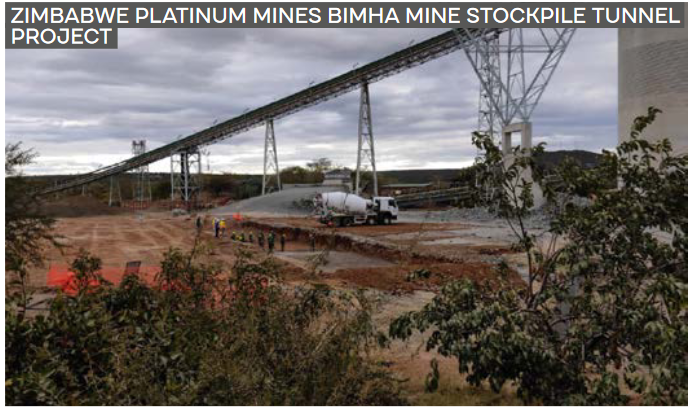

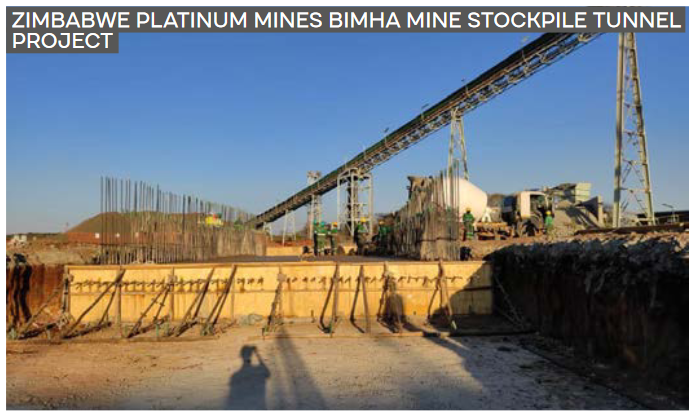

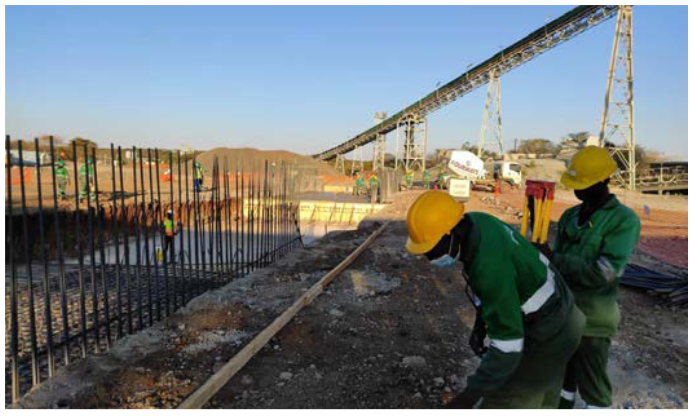

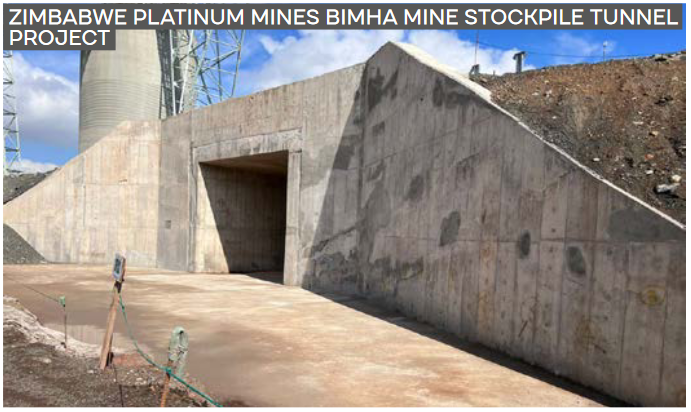

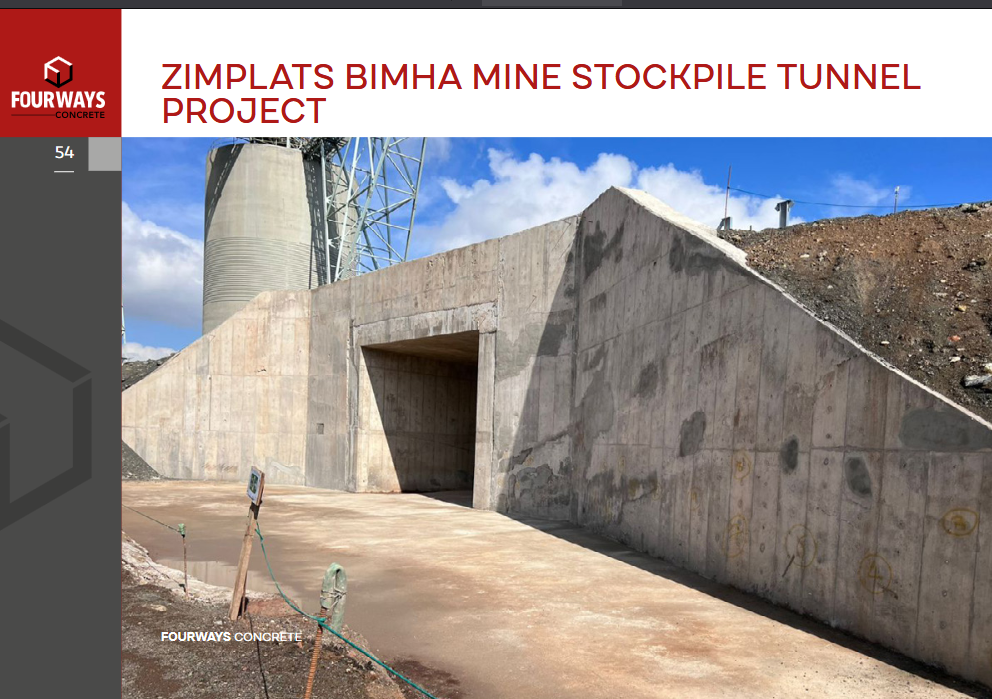

Bimha Mine 3MTPA Upgrade – Surface Infrastructure

The Challenge: Powering a Major Production Upgrade

As part of the Bimha Mine’s major 3 Million Tonnes Per Annum (3MTPA) upgrade, Zimplats required a partner capable of delivering the foundational concrete works for critical surface infrastructure. The project’s complexity involved constructing robust foundations for the new stockpile, numerous conveyor belt bases, and the main office buildings, all of which had to be built to withstand heavy industrial use and integrate with existing operations.

The Fourways Solution: Precision and Durability

Our team provided a turnkey solution for all concrete works associated with the surface upgrade. We meticulously planned and executed the construction of high-tolerance foundations for the conveyor systems, ensuring perfect alignment and long-term operational integrity. For the stockpile and office buildings, we delivered durable, high-strength concrete structures built to the highest quality standards, providing a solid foundation for the mine’s expanded operational capacity.

The Impact:

Our contribution to the Bimha surface upgrade provided the essential backbone for the mine’s increased production. The quality and precision of our work ensure the reliability and longevity of this critical infrastructure, directly supporting Zimplats’ growth and operational efficiency.

Project Showcase 3:

Bimha Mine Crusher Project – Underground Construction

The Challenge: Complex, Multi-Disciplinary Underground Construction

The Bimha Crusher project was a highly complex, multi-faceted undertaking deep within the mine. The challenge was to lead a construction team in a confined underground environment to build a variety of critical structures. This included underground dams for water management, high-strength plinths for conveyor belts, foundations for the primary jaw crusher, Motor Control Centers (MCCs), and the associated loading bays, rock-breaker, and grizzly foundations.

The Fourways Solution: Expert Leadership in a Specialized Environment

Fourways Concrete took the helm of the construction team, providing the expert oversight and technical skill required for this specialized project. Our leadership ensured that each component was constructed to precise engineering specifications. We managed the logistical complexities of moving materials and equipment underground and executed the construction of robust, vibration-resistant foundations designed to handle the immense forces generated by the crushing equipment.

The Impact:

By successfully delivering the entire suite of civil and concrete works for the crusher project, we created a fully integrated, functional, and durable underground processing hub. This project showcases our specialized expertise in underground construction and our ability to lead complex, multi-disciplinary teams in challenging environments.

Project Showcase 4:

Ventilation Systems & Shotcrete Innovation

The Challenge: Enhancing Safety and Efficiency in Ventilation Shafts

The final piece of our work involved constructing the civil and concrete foundations for the mine’s critical ventilation fans. During this phase, a key challenge emerged: the need for a more effective and efficient method for sidewall stabilization within the ventilation shafts. The goal was to find a shotcrete solution that offered superior strength and adhesion while also being more cost-effective and faster to apply.

The Fourways Solution: Material Science and Innovation

This is where our commitment to innovation came to the forefront. Instead of relying on standard materials, our technical team developed and implemented a new, more effective shotcrete mix. This custom-formulated material provided enhanced strength and better bonding characteristics, significantly improving the stability and safety of the shafts. This innovative solution was not only technically superior but also optimized the project’s budget and timeline.

The Impact:

The development of our advanced shotcrete material is a clear example of our identity as problem-solvers. It demonstrates our ability to go beyond simple construction and leverage material science to deliver tangible improvements in safety, cost-effectiveness, and project efficiency for our clients.

Project Showcase 5:

Mupani Mine

The Challenge: The workshops at Mupani Mine required concrete repair work to restore their structural integrity and ensure a safe working environment.

This project demanded a thorough understanding of concrete deterioration and the application of appropriate repair techniques.

The Fourways Solution:

Our team conducted a detailed assessment of the damage and implemented a comprehensive repair plan. We utilized high-quality repair materials and advanced techniques to restore the concrete surfaces to their original strength and durability.

The Impact:

Our expert repair work extended the service life of the workshops, ensuring their continued safe and efficient operation. This project highlights our expertise in concrete rehabilitation and our commitment to maintaining the long-term value of our clients’ assets.

Project Showcase 6:

New Tailings Storage Facility (TSF) Mimosa Mine.

The Challenge: Zero-Failure Tolerance in Environmental Engineering

The primary challenge in constructing a new tailings facility is the absolute necessity for perfection. The project required the placement of 12,000m³ of concrete to create a secure, impermeable, and durable containment system. In this high-stakes environment, there is no margin for error. Any compromise in material quality or construction integrity could have significant, long-term environmental and operational consequences. The project demanded a partner capable of delivering a large volume of concrete while adhering to the most stringent quality control protocols ever devised.

The Fourways Solution:

A Culture of Quality and Proactive Control We approached this challenge not just as a contractor, but as a guardian of the project’s integrity. Our solution was to implement a rigorous, multi-layered quality assurance program that was integrated into every stage of the project. This included:

Custom Mix Design: Developing a specific concrete mix designed for maximum durability and impermeability, tailored to the unique geochemical environment of the tailings.

Stringent Material Vetting: Sourcing and testing all raw materials to ensure they met and exceeded project specifications.

Continuous On-Site Testing: Our technical teams were a constant presence on-site, performing slump tests, taking cylinder samples for compressive strength testing, and monitoring every single pour in real-time.

This proactive, meticulous approach to quality control was the cornerstone of our “concreting solution.” We didn’t just supply concrete; we guaranteed its performance.

The Impact: 12,000m³ Poured, Zero Quality Issues

The result of our unwavering focus on quality was a flawless project run. Over the entire placement of 12,000m³ of concrete, we did not experience a single quality issue. This perfect track record is not an accident; it is the direct outcome of our deeply embedded culture of excellence and our technical expertise. For Mimosa Mine, this meant complete peace of mind and the assurance of a safe, reliable, and environmentally secure tailings facility that will stand the test of time. This project serves as the ultimate proof of our reliability and our position as the industry benchmark for quality.

Project Showcase 7:

Kunzvi Dam Development

The Challenge: A Multi-Faceted Engineering Endeavor on a National Scale

The construction of Kunzvi Dam is not a single project, but a series of complex, interlocking civil engineering challenges. Each component demands a unique approach, a specific concrete solution, and flawless execution to ensure the dam’s structural integrity and operational longevity for generations to come. Our role required us to tackle four distinct, large-scale concreting operations simultaneously.

The Fourways Solution: Phased Execution and Specialized Concrete Engineering

We have structured our involvement into distinct, expertly managed phases, each with its own technical solution:

1. Ground Stabilization & Foundation Integrity (Completed):

The Task:

Initial ground investigations revealed areas of incompetent rock and soil that lacked the required load-bearing capacity for the dam’s core structures.

Our Solution:

We successfully placed 4,000m³ of mass concrete to remediate these areas. This foundational work involved creating a monolithic, stabilized base, effectively transferring the immense structural loads of the future dam into competent bedrock and ensuring total stability. This phase was critical for mitigating settlement risk and was completed successfully.

2. Hydraulic Channeling & Water Management (Nearing Completion):

The Task:

To manage the controlled flow of water, a massive box culvert pipe channel was required.

Our Solution:

We are currently finalizing the placement of 4,500m³ of high-strength concrete for this extensive channel. The work demands precision formwork and a durable concrete mix designed to withstand constant hydraulic pressure and abrasion, guaranteeing efficient water conveyance for the life of the dam.

3. Core Structural Works (Commencing):

The Task:

The next phases involve constructing the two most iconic and structurally demanding elements of the dam: the spillway and the intake tower.

Our Solution:

We are now mobilizing for these critical placements. The 22,000m³ spillway will require a meticulously planned, continuous pour schedule using a specialized concrete mix designed for maximum erosion resistance and structural strength. Simultaneously, the 2,800m³ intake tower, a complex vertical structure, will demand intricate formwork and a high-performance concrete mix to ensure it can withstand immense hydrostatic forces.

The Impact (In Progress):

Our work at Kunzvi Dam is a live demonstration of our capacity to deliver on large-scale, public infrastructure projects. By successfully completing the foundational mass concrete works and nearing the completion of the box culvert, we have already established a solid platform for the project’s success. As we embark on the spillway and intake tower, we are not just pouring concrete; we are actively contributing to a legacy of progress, engineering a vital resource that will serve Zimbabwean communities for a century to come. This project is a powerful symbol of our commitment to building the nation.

Project Showcase 8:

RZM Murowa “Project Crown Jewel” Processing Plant

The Challenge: Engineering a High-Performance Industrial Ecosystem from the Ground Up A “Greenfields” project of this magnitude presents a formidable challenge:

Transforming an undeveloped site into a complex, high-performance industrial ecosystem. The success of the entire RZM Murowa plant hinged on the absolute integrity of its civil foundations. The project demanded a concrete supplier capable of delivering 6,500m³ of material, not just in volume, but in a variety of specialized, high-performance mixes. Each structure, from the vibration-intensive crusher platforms to the massive stockpile tunnels, required a unique concrete solution engineered to withstand specific operational stresses.

The Fourways Solution:

Precision, Partnership, and Performance In our crucial role as the project’s concrete supplier, we worked in close partnership with Tencraft Construction to ensure every pour was a success. Our solution was centered on delivering tailored performance and logistical excellence:

1. Vibration-Resistant Foundations:

For the crusher and processing platforms, we engineered and supplied a high-strength, vibration-dampening concrete mix. This was essential to create foundations that could absorb the immense, continuous dynamic loads from the processing machinery, ensuring long-term structural stability and operational safety.

2. Load-Bearing Superstructures:

The thickener foundation and the nine extensive stockpile tunnels required massive, monolithic pours. We supplied a durable, high-load-bearing concrete mix designed to support the immense weight of the structures and the processed materials they would contain.

3. Consistent Quality Across the Board:

From the primary industrial structures to the various ancillary buildings, we maintained a rigorous quality control regime, guaranteeing that all 6,500m³ of concrete met or exceeded the stringent engineering specifications set by the project.

The Impact: A Foundation of Trust and Excellence Our successful delivery on “Project Crown Jewel” is a powerful testament to our capabilities as a strategic supply partner.

By providing a consistent, high-quality, and precisely engineered product, we empowered the civil contractors to meet their tight construction deadlines and deliver a world-class processing plant for RZM Murowa. This project showcases our ability to perform under pressure and reinforces our reputation as the go-to concrete supplier for Zimbabwe’s most critical and complex industrial developments.

Partner with Fourways Concrete for Your Next Project

Your vision deserves a partner who can match your ambition. At Fourways Concrete, we are ready to bring our strategic expertise, innovative solutions, and unwavering commitment to your next project.

Contact us today for a project consultation and discover how we can engineer your success.